Different from the workflow of other rice merchants who purchase wet rice, Fenggu Company has modified the rice drying process to pursue better profits and provide farmers assuring services. The company has expanded the capacity of rice drying to create better profits margin for itself and for farmers.

Freshly harvested rice is shipped by a truck to Fenggu Company. From this moment, the rice needs to go through the following procedures:

1.Weight measurement:

The truck drives through a truck scale, so that the weight of the wet rice can be derived and translated into the purchase price.

2.Visual inspection:

Some wet rice is sampled from the truck, to check for the grain size, ripeness, impurities, and quality.

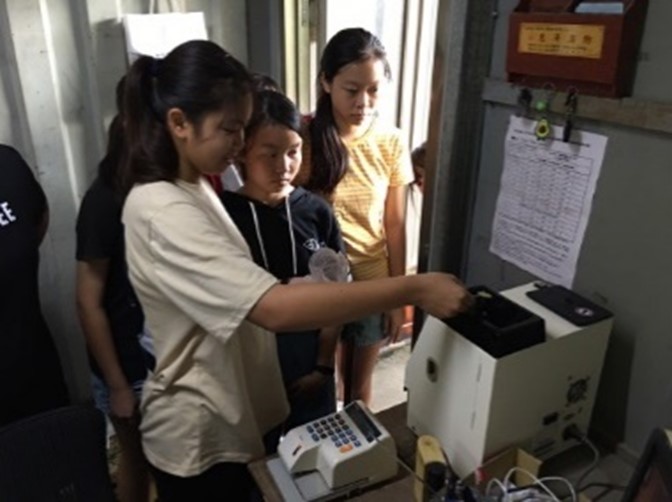

3.Water content inspection:

An electronic measuring machine is used to inspect the water content of the wet rice. This is to decide the time for the wet rice to stay in the barrels.

4.Sampling:

The visually inspected rice is placed into a wet rice pouch and hung in the wooden shelf in an airy location. This pouch is numbered, waiting for the results from the spot inspection by the Agriculture and Food Agency for pesticide residues or prohibited chemicals. This is a process designed by Fenggu Company to ensure food safety.

5.Wet rice barrels:

Fenggu Company’s wet rice barrel has a full capacity of 700 metric tons. Wet rice purchased from farmers is parked in the barrel before drying. The purpose is to put different batches of rice into a close contact to each other so that the water content becomes consistent at 25% to 35%. This avoids the difficult in quality control due to overly large variances in water content of different batches in the drying process. It also reduces the drying time and cost. The shortening of each drying cycle means more cycles over the same period of time and hence larger throughputs and higher profits.

6.Sieving:

Before the wet rice removed from the wet rice barrel goes into the dryer, the rice must go through a sieving machine first to remove most husks and some impurities. This protects the dryer from damages. It also enhances the quality of dried rice. The reduction of impurities brings down the drying cost and makes packing easier.

7.Drying:

This step is to dry the wet rice sieved by the machine. The purpose is to reduce the water content so that rice can be stored. The level of dryness required is different for each rice. Glutinous rice needs to be dried, with low heat, for long hours. Japonica rice is quicker. Indica rice also needs to be on low heat. Rice can be purchased by the government or sold to the market. Rice purchased by the government needs to keep a lengthy period so the water content must be reduced to 13%. However, this makes government-purchased rice taste not as good. Rice to be sold to the market is for immediate consumption. To maintain a good and moist texture, the required water content is 16%.

Different from other rice dryers who use diesel, Fenggu Company burns husks for the heat source. The ashes can be maintained at 55°C for rice drying. This significantly lowers the cost. The ashes can be used for the manufacturing of steel or potting soil. This method is environmental-friendly. The full capacity of a dryer is 245 metric tons. Each cycle is about 24 hours, without any disruption.

8.Cooler barrels:

Dried rice can be packed directly and shipped to farmers’ associations for stockpiling if to be purchased by the government. If the dried rice is for the open market, it will be stored in a cooler barrel at 15-17°C for storage.

9.Packaging:

Rice quantity is measured by a machine for packaging. If purchased by the government, the dried rice is packed and transported to farmers’ association for stockpiling. The rice for the open market is then stored in a cooler barrel and sold to buyers in due course.

2020.08.04, 2020.08.28, 2020.11.15 interview records

Taken by our team member

top

top  Homepage

Homepage